NORTHAMPTON, MA / ACCESSWIRE / August 16, 2024 / Schneider Electric

Schneider Electric

Circularity is the philosophy and practice of using less, using better, using longer and using again – conserving resources to get the maximum benefit from them. This is not only common sense, but also good business sense.

A sea of untapped possibilities

Every year, enormous amounts of garbage are washed up on the coasts – a heavy burden on our planet and a symbol of inefficiency.

Our global circularity rate is declining. According to the Global Circularity Gap Report 2024, the share of secondary materials used worldwide has continued to increase, but has fallen significantly from 9.1% in 2018 to 7.2% in 2023.

Consider the scale of the missed opportunity: the circular economy alone could save nearly 75% and 60% of CO2 emissions from the construction and transport sectors respectively by 2050. And with an estimated potential GDP increase of 7% by 2030, the circular economy is more than just green, it is a growth line. From the EU’s Circular Economy Action Plan to the US’s National Recycling Strategy, policies and incentives already exist to provide a framework.

Changes such as the regionalisation of supply chains are also leading to circular practices such as better sourcing, smarter production and more remanufacturing, recycling and repairability. This is good news because, given the urgency, we must realise the potential of the circular economy. It is key to transforming our businesses into catalysts for efficiency, resilience and sustainable value creation.

From systematic to systemic change

Like all carbon footprint reduction programs, circular transitions require a systematic approach: initiatives underpinned by measurable and complementary objectives and driven by both internal and external stakeholders.

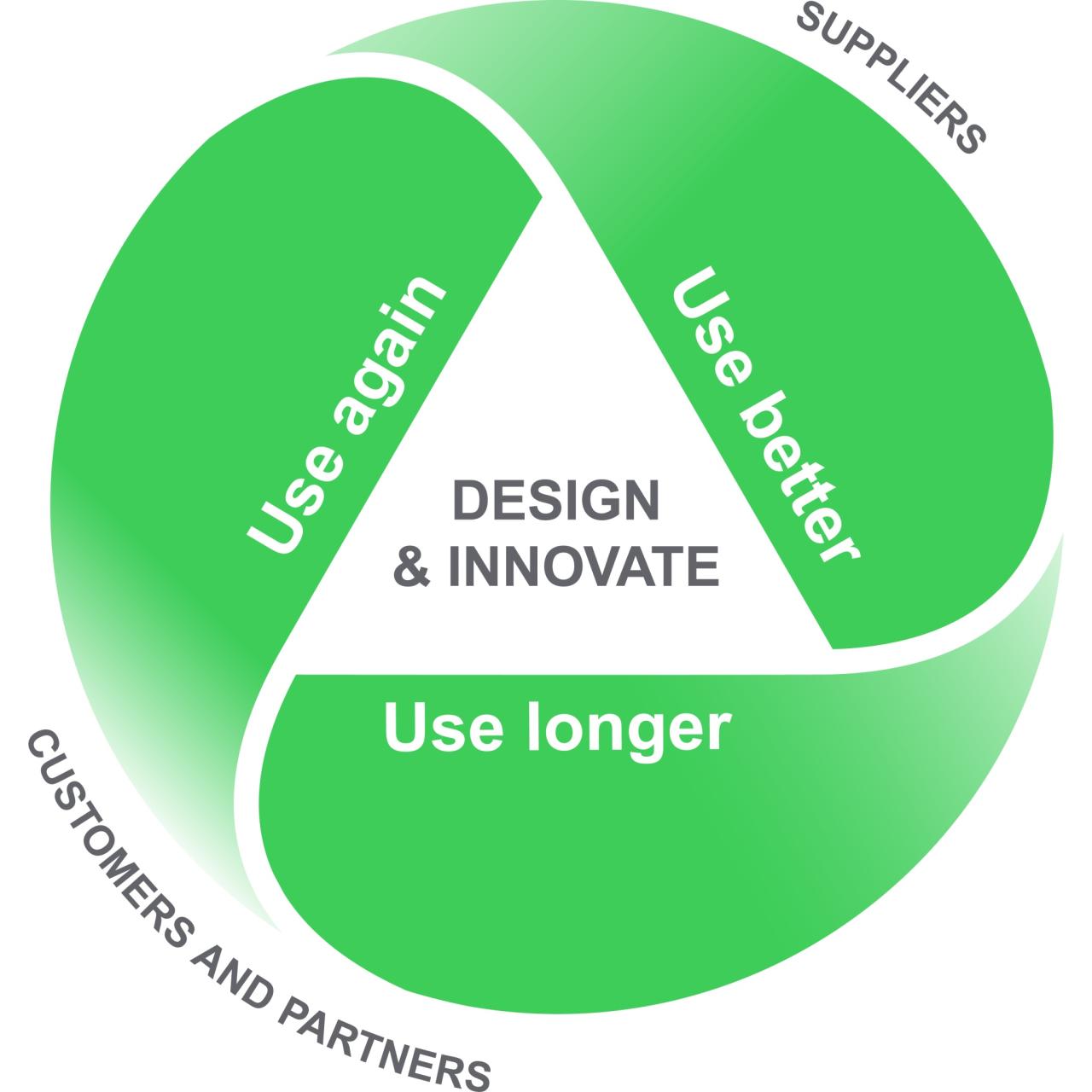

Furthermore, the systemic nature of circularity also requires more changes than just linear approaches. It also requires a transformation happening “everywhere at once” in all aspects of consumption and production. This process consists of four phases: Design & Innovation, Use Better, Use Longer and Reuse – and requires a coordinated change in mindset.

These requirements form the basis for Schneider Electric’s transformation process.

Smarter, better, more circular

At the heart of a circular transformation is the Design & Innovation phase, which impacts product development and innovation. This phase plays a critical role in maximizing value retention and influences up to 80% of a product’s lifecycle impact. At Schneider Electric, we regularly revitalize and implement our EcoDesign tools and training. These support teams such as R&D deliver more value through additional reliability and longer lifespan and develop new as-a-service solutions.

The ‘Use Better’ phase is about sourcing materials and producing products as sustainably as possible and with minimal waste. For example, by using better sourcing strategies, we were able to increase the share of sustainable materials from 7% in 2021 to 29% in 2023, with the aim of reaching 50% in 2025. Likewise, we increased the share of sustainable packaging from 13% to 63% during the same period. The aim is to use 100% primary and secondary packaging without single-use plastic by 2025.

In addition to the use of recycled materials and renewable energy, smart factory operations – such as digitized manufacturing, connected machines, and data and analytics – also contribute to the circular economy by creating new forms of efficiency and flexibility. For example, within four years, our Hyderabad plant reduced its energy consumption by 59%, water consumption by 57%, and CO2 emissions by 61% while improving waste optimization by 64%. It was recognized as a “Beacon of Sustainability” by the World Economic Forum in 2023.

The Use Longer phase helps extend the life of products to delay the need for new products. It includes condition-based repairs and digitally-enabled equipment maintenance and modernization services. For example, we decided to introduce a range of ECOFITtm retrofit services to facilitate equipment upgrades by replacing specific key components rather than the entire system.

Finally, the Reuse phase covers the recycling of products, parts and materials in the economy. This includes the refurbishment and resale of assets that have reached the end of their useful life. In our refurbishment and repackaging pilot program in France, we use digital traceability and reverse logistics for the end-of-use phase. Once a product is retrieved from Schneider Electric, we assess whether it should be repaired, reused, refurbished or recycled. When remarketing the product, we also take into account all relevant information, including performance. In this way, we have avoided the consumption of over 300,000 tonnes of primary resources since 2017.

While each step plays a critical role, it is important to understand the natural hierarchy within this approach. The cost of recovering value tends to increase over the product lifecycle. For example, it is much more efficient to optimize the use of raw material at the design stage (“use better”) than to recover raw material from products at the end of their use (“reuse”). This is the best way to maximize value retention throughout the asset’s lifecycle.

Setting the path

At Schneider Electric, our commitment to circularity began over two decades ago and continues today. With a focus on sustainable innovation and a close collaboration with the Ellen MacArthur Foundation in 2015, our goal remains to take the concept of circularity from theory to the core of our business.

We have seen that the path is not always straight. It has to be smarter, better and more circular. And that can only be achieved together.

For more multimedia content and more ESG storytelling from Schneider Electric, visit 3blmedia.com.

Contact information:

Speaker: Schneider Electric

Website: https://www.3blmedia.com/profiles/schneider-electric

E-mail: (email protected)

SOURCE: Schneider Electric