Rivian presents at SEMA how process development and testing impact repair results

From

To

Announcements

The process an automaker goes through to research, develop, validate and publish new repair procedures will be the focus of a presentation by Rivian representatives during the Society of Collision Repair Specialists (SCRS) OEM Collision Repair Technology Summit at the 2024 SEMA Show in Las Vegas.

“Viewers will gain a better understanding of how automakers prioritize the development and scheduling of procedures and how rigorous testing protocols can lead to greater efficiency in the development of similar future procedures across the vehicle,” a press release said.

The session will also discuss how evolving vehicles, materials, technologies and trends impact repair processes and companies.

Rivian’s research, development, service and collision teams will present on Thursday, November 7 at 12:30 p.m. during “Session I: Value of OEM Repair Information,” one of three sessions of the OEM Repair Technology Summit.

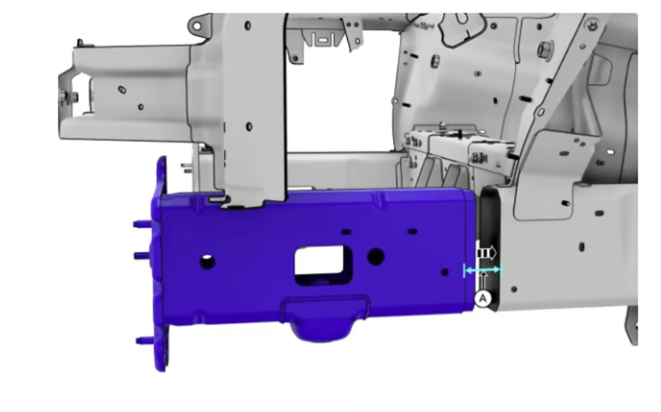

David Sosa, Rivian’s Collision Research and Development Shop Manager, Dan Black, Rivian’s Senior Service Engineering Manager, and Kelly Logan, Rivian’s Service and Collision Repair Program Manager, explain the validation process the company used to develop test solutions to ensure the vehicle owner receives a repair that meets specific safety and performance aspects.

The panel will review the testing methodology, the press release said. In many cases, it will reflect the protocol used in the manufacturing process. It will also illustrate the timeline for approval using unique visual examples.

“This session truly epitomizes what the OEM Summit should accomplish for the industry,” SCRS Chair Amber Alley said in the press release. “We have always worked hard to provide speakers and content that provide the repair industry with insight into the latest developments in the repair industry. This team and the case study they are sharing with the industry are a testament to the OEMs’ commitment and responsiveness to real-world needs and the complexity involved in developing the available information used to make safe and proper repairs. I personally am very excited to learn from this session and bring it to my team.”

Black also spoke about the use of Aluminium and composite materials on the riseTo watch a video of the session, click Here.

Visit www.scrs.com/rde to register for Repairer Driven Education sessions, or use the SEMA Map Your Show site to view all available courses in the SCRS Repairer Driven Education (RDE) course.

For more information about SCRS or membership, visit www.scrs.com, call 1-877-841-0660, or email [email protected].

Pictures

Featured photo courtesy of Rivian.

All other photos courtesy of SCRS.

Split:

Related